Vandskæremaskiner har revolutioneret måden, hvorpå der skæres og bearbejdes i forskellige industrier, og leverer en præcision, der er uden sidestykke, og uden varmebetinget forvrængning som ofte ses ved andre skæremetoder. Vandskæremaskiner har udviklet sig med tiden, og deres alsidighed gør dem til et fremragende værktøj til skæring af komponenter til luftfart, bildele, stenarbejdsplader og industrielle værktøjer. Så når du er klar til at købe en vandskæremaskine, hvor kan du så finde den bedste waterjet-maskine til salg ? Denne artikel guidar dig igennem de bedste muligheder, de ting, du bør overveje, inden du køber, og hvorfor producenter som Fujian Jingyang Intelligent Equipment Manufacturing Co., Ltd (Stone Machinery Pro) bør være på din liste.

Vandstråleteknologi forklaret

I en vandstrålemaskine bruges en højtrykket vandstråle – nogle gange med abrasive partikler – til at skære igennem meget hårde materialer. Nogle af de materialer, der ofte bearbejdes med vandstråle, inkluderer metaller, kompositter, sten, glas, keramik osv. Den største fordel er den kolde skæring, som undgår varmepåvirkede zoner, deformation eller mikrorevner, der kan mindske materialets holdbarhed. Derudover kan vandstråler bevare strukturel integritet i materialerne, selv i de mest følsomme applikationer, i modsætning til laser- eller plasmaskærere.

De vigtigste grunde til, at virksomheder vælger vandstråleskæring

- Præcision og alsidighed: En vandskære-maskine kan bruges til at skære meget komplekse former med stor nøjagtighed, ofte ned til yderst små detaljer.

- Materialeuafhængig: En vandskære-maskine kan skære både meget bløde og meget hårde materialer som aluminium, granit, glas, titanium osv.

- Ingen varmeskader: Laserstrålen forårsager ikke smeltning, brænding eller forvrængning af emnet.

- Mindre spild: En perfekt og ren kant betyder mindre tid brugt på polering og efterbehandling.

I lyset af disse egenskaber er en vandskære-maskine et meget klogt investeringsvalg for fabrikeringsværksteder, industrielle producenter og stenbearbejdende virksomheder, der ønsker at udvide deres serviceydelser og maksimere fortjenesten.

Hvor køber man en vandskære-maskine?

1. Fabriksdirekte

Den bedste og mest pålidelige måde at købe en vandskære-maskine på er fabriksdirekte fra en højt agtet producent. At gå direkte til kilden giver dig generelt større muligheder for tilpasning, teknisk support samt garantier for ydelse og service.

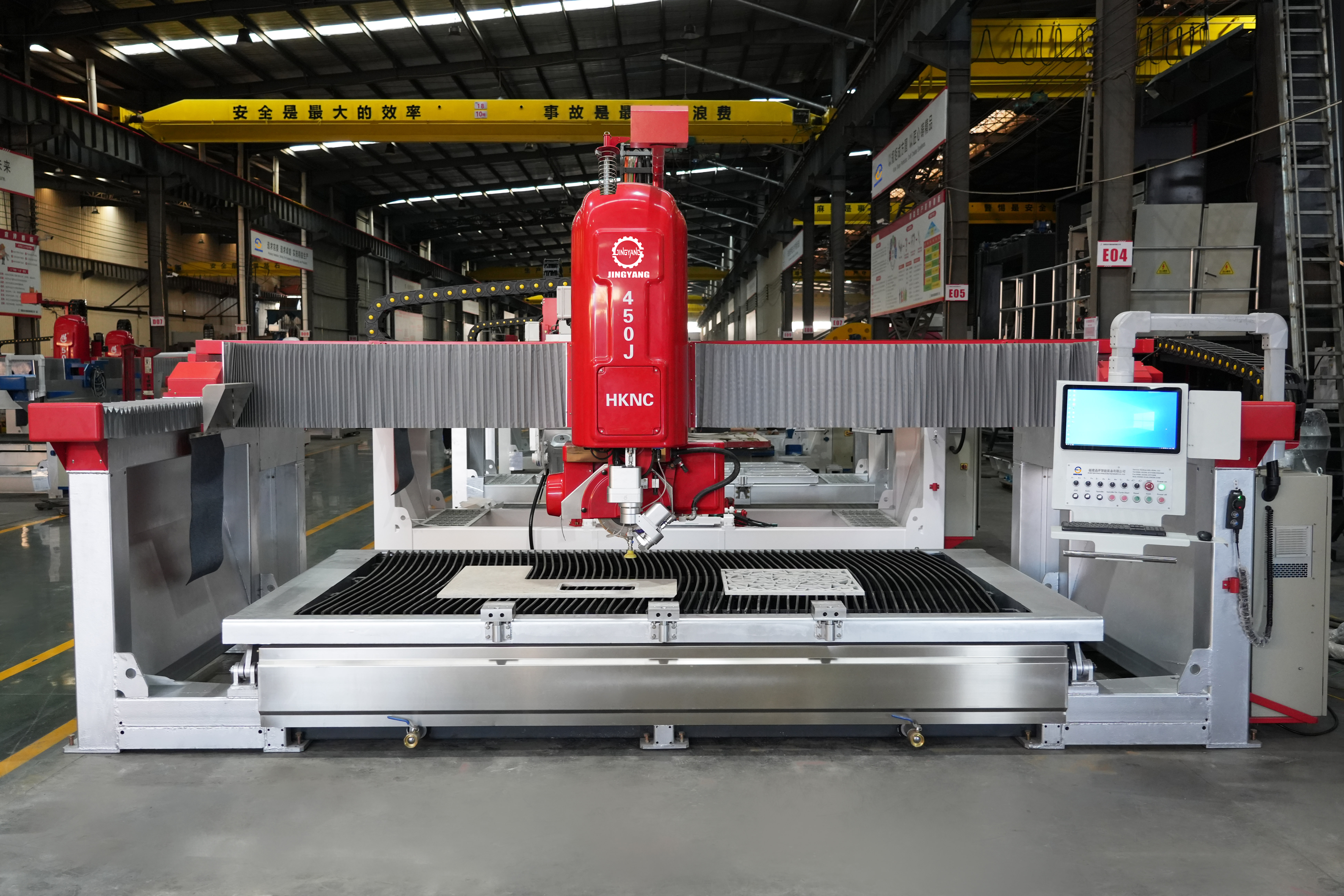

Stone Machinery Pro (JingYang)

Overraskende nok er et sådant firma Fujian Jingyang Intelligent Equipment Manufacturing Co., Ltd, også kendt som Jingyang Stone Machinery Pro. Selskabet blev grundlagt i 1997 og har mere end 35 års erfaring inden for stenmaskiner, opnået gennem integration af design, forskning og udvikling, produktion, salg og eftersalgsservice i én enhed.

De har en produktionsanlæg på 50.000 m², og deres system til total kvalitetsstyring er certificeret efter ISO 9001:2015, miljøstandarden er ISO 14001, og overensstemmelse med EU's CE-krav er ligeledes opfyldt. Alt dette symboliserer et pålideligt mærke, der leverer produkter af god kvalitet og har evnen til at række ud på det globale marked.

De har et helt sortiment af skæremaskiner, der omfatter vandskærere, CNC-vandskærere og flerakse vandskærere. Hver enkelt maskine er designet med gode funktioner som præcision, holdbarhed og kontinuerlig drift i tankerne. Maskinerne er udstyret med meget højtrykspumper, der kan løbende udskille ekstremt fine vandstråler, hvilket resulterer i et minimalt spild ved skæring af komplekse sten- og metalformer.

At gå direkte til en producent som Jingyang sikrer dig:

- Tilpasning: Alt skræddersyet efter din produktionsproces samt dit tilgængelige rum.

- Eftersalgsunderstøttelse og træning: Installationssupport og teknisk hjælp efter salget indgår i pakken.

- Global serviceorganisation: Selskabet har kontorer i Europa, Nordamerika, Mellemøsten og Sydøstasien.

En af fordelene ved at købe direkte fra fabrikken er, at hvis du lægger vægt på pålidelighed, service og teknisk support over lang tid, vil du altid være dækket.

2. Markedsplads for industriudstyr

Udover at købe maskiner direkte fra producenterne, kan du også købe dem via specialiserede markedspladser for industriudstyr, som er tilgængelige online. På disse hjemmesider får du vist alle slags vandskæreanlæg fra forskellige mærker – både nye og brugte – hvilket gør det nemt for købere at sammenligne funktioner og priser:

- StoneContact: Er en side for grossist- og detailhandel med teknisk udstyr, hvor du finder flere leverandører af CNC-vandskære- og 5-akse skæresystemer fra hele verden. På siden kan du få adgang til priser samt tekniske specifikationer.

- MachineTools.com: Er et websted, der viser vandskæremaskiner i USA og Canada. Det kategoriserer dem desuden efter størrelse, pumpepres, og stand (nye, brugte, demonstrationsenheder).

Markedspladser kan være de bedste steder for følgende:

- Overkommelige muligheder: For eksempel brugte eller reconditionerede enheder.

- Sammenligning: Mulighed for at se på de forskellige mærker samtidig.

- Et bredt udvalg af produkter: Fra de mindste og mest kompakte vandskæreanlæg til store industrielle vandskæresystemer.

På den anden side: Køber betaler! At købe på denne måde betyder næsten altid, at du selv skal udføre grundigt research vedrørende garantier, transportordninger og service efter salget. Derfor er det bedre at gøre sin grundige research, inden man går til indkøb.

3. Autoriseret forhandler og distributør

Vandskæreanlægsproducenter har typisk autoriserede forhandlere, som lagrer deres produkter lokalt og tilbyder demonstration, installation og support på stedet. Kunder kan:

- Afprøve forskellige maskiner for at finde ud af, hvilke der passer bedst til deres arbejdsproces.

- Få hjælp til finansiering, leasing eller fastlæggelse af betalingsplaner.

- Få de nødvendige vedligeholdelses- eller serviceserviceaftaler.

For eksempel leverer OEM-partnere, der samarbejder med velkendte mærker som KMT Waterjet, højtrykspumper og skæresystemer gennem deres globale netværk af forhandlere. Derfor kan købere få adgang til det rigtige produkt til deres behov fra forskellige dele af verden.

I tilfælde af forhandlere:

- Bekræft deres godkendelser og om de er autoriserede.

- Find ud af, hvor hurtigt de vil reagere på en serviceanmodning.

- Bed om en liste over tilfredse kunder.

Ting, der skal gennemgås, før du foretager et køb

Processen med at købe en vandskære-maskine indebærer mere end blot at vælge et mærke. Det handler om, om maskinen matcher de specifikationer, du kræver.

1. Arbejdsområde og bæreevne

Du bør først identificere dimensionerne på de emner, du vil bruge til skæring. Det er sandt, at større modeller tillader dig at arbejde med større plader, men ulempen er, at de også vil kræve, at du betaler en højere startpris og har mere plads til rådighed.

2. Vandtryk og pumpeydelse

Pumper, der leverer højt vandtryk (mindst 60.000 psi), kan normalt skære materialer med større præcision og i et hurtigere tempo. Find ud af alt om pumpen, herunder typen, vedligeholdelseskrav og ydelse.

3. CNC og aksekonfiguration

Der findes et bredt udvalg af maskiner, fra enkle basale XY-CNC-modeller til avancerede femakse-systemer, som er i stand til at lave skråskæringer og komplekse 3D-skæringer. Med flerakse vandskæring kan du markant øge din produktionskapacitet, men der vil være yderligere omkostninger i starten.

4. Leverandørsupport og uddannelse

De bedste producenter og forhandlere tilbyder et stort udvalg af tjenester såsom installation, uddannelse, software-support samt vedligeholdelse og reparation; disse er vigtige faktorer for at holde udstyret funktionsdygtigt og derved sikre afkast på investeringen.

5. Garanti og servicesystemer

Det er afgørende at sikre, at din vandskære-maskine er omfattet af garanti for hardware med rimelige vilkår og understøttet af producentens service netværk, der kan yde hurtig service, når der opstår et problem.

Tips til omkostningsreduktion

- Se på brugt udstyr: På andenhandsmarkedet finder du mange enheder, der knapt er blevet brugt og har en høj bæreevne, og som sælges med meget stor rabat.

- Forhandl installationsaftaler: Visse forhandlere inkluderer opsætning og træning for første gang-brugere i deres tilbud uden ekstra omkostninger.

- Køb i gruppe: Hvis der skal købes mere end én maskine, kan du forhandle med producenterne om mængderabatter.

Sammenfatning

Processen med at finde de bedste vandskæreanlæg til salg bliver meget lettere for dig, når du har et klart overblik over dine behov, har udført grundig research på anerkendte sælgere og fundet pålidelige samarbejdspartnere. Det betyder ikke noget, om du er en producent, der ønsker at skaffe dit første præcisions-skæresystem, en stenskærer, der søger måder at udvide dine ydelser på, eller en industriproducent, der øger produktionen – med det rigtige vandskæreanlæg kan du helt sikkert forbedre din arbejdsgang markant.

Først og fremmest bør du overveje at søge direkte hos producenter som Fujian Jingyang og anerkendte markedspladser. Læg mærke til pumpekraft, styresystemer, eftersalgssupport og den samlede ejerskabsomkostning. Med det rigtige valg får du mulighed for rene skær, bredere ydelsesmuligheder og en stærk konkurrencemæssig fordel.