Selecting the perfect granite cutting machine is a very crucial decision for stone fabricators, construction companies, and countertop manufacturers not only in Europe and North America but everywhere else in the world as well. Granite is well known as one of the hardest natural stones and it is highly prized for its durability and exquisite appearance; however, the very features that make it attractive also make it difficult to produce without quality, high-capacity equipment.

In this article, the author tried to find out if it makes sense to invest money in a granite cutting machine, share the tips for potential buyers on what to consider before making the purchase, and explain how a reputable manufacturer like JingYang can assist a business in stepping through the risks, thus, getting more return on investment.

Granite is a very dense, abrasive matter and does not tolerate poorly quickly. As a result, a huge number of purchasers are not conscious of the fact that their machines of low quality can be easily worn out and their production with such machines can be inefficient due to highly inconsistent cutting.

Typical industry issues are:

Workshops that are engaged in handling big slabs or large volume orders are turning these issues into challenges for the speedy earning of profits. Which is why a decision to purchase a granite cutting machine should be based on knowledge of the machine’s long-run performance and reliability and not simply on the price.

A high-end granite cutting machine can be a smart investment with benefits being very evident in the following respects:

Top-of-the-line CNC cutting systems provide perfection of the cut every single time which, in turn, leads to smallest waste of materials and less rework.

Automation of the cutting process and the consistency of the CNC controlled structure lead to the increase of the processing speed with even less operator intervention.

Although the upfront cost may look unsightly, robust parts and less wear and tear translate into much less operating cost over the long term.

New generation machines not only straighten cuts but also bevels, curves and can do sink holes thus, creating the potential to explore new markets.

When a 5 to 10 year usage period is taken into consideration, a top-grade granite cutting apparatus amounts to a self-funded equipment rather quickly.

JingYang under the management of StoneMachineryPro is a reputable manufacturer of stone machinery that has around 35 years of experience in the industry. As per the company's introduction (https://www.stonemachinerypro.com/about-us), JingYang is a whole process provider that integrates research, manufacturing, quality control, and global service.

Some key qualities that make buyers hand over their money to the company are:

Such a size and knowledge pool that the company has enables JingYang to provide solutions such as granite cutting machines for the most challenging working environments on a consistent basis.

Buyers from Europe and America always require thorough compliance with standards and safety regulations. JingYang production facilities are under strict supervision of the quality control department. The company has already got certified with:

Every granite cutting machine is thoroughly tested for 24 hours to ensure stability, accuracy, and durability in the actual working environment before the shipment. Such a level of quality control causes the risk of unexpected equipment breakdowns right after the installation to diminish hugely.

JingYang is renowned for its continuous innovation due to long-standing R&D work in the company. Over the years, the company has gotten a lot of patents and has actively been involved in standard-setting activities of the industry. In close collaboration with some universities, the firm keeps re-designing the structure, control system, and cutting efficiency of the machines.

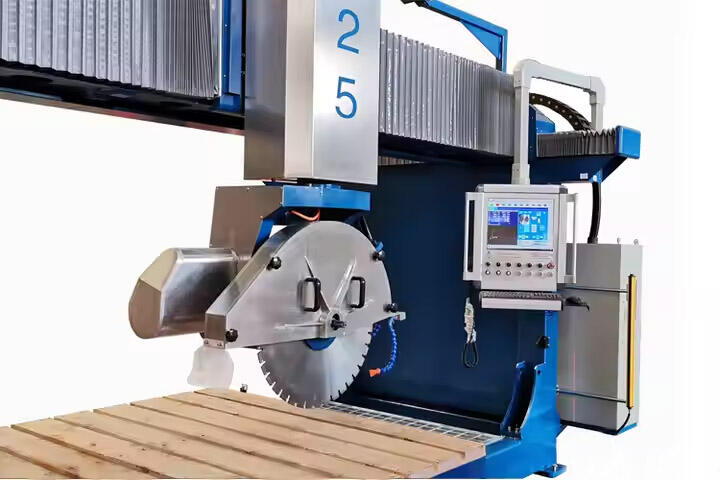

JingYang granite cutting machines of the latest generation feature the following characteristics:

These characteristics aimed at helping users in getting flawless cuts, smooth edges, and high mechanical throughput.

It is unlikely to find a professional granite cutting machine that is not engaged in the following activities:

Whatever the task is, the machine becomes the main production tool for stone processing businesses.

Reliability and service aspects, in particular, have been often mentioned by customers from the West.

"We immediately saw an improvement in our cutting accuracy after we switched to a JingYang granite cutting machine. We also saw a really big drop in the amount of the wasted material."— Stone Fabricator, Germany

"And the thing that wowed us was the stability of the machine combined with the support from the technical department. The whole installation and training process was very professional."— Countertop Manufacturer, USA

"We operate the machine on a daily basis, cutting hard granite slabs and our output has been stable all this time."— Stone Processing Company, Italy

The above-mentioned reviews are a mirror of how the quality of the equipment and after-sales service can have a direct impact on the customer satisfaction that lasts over time.

JingYang has partnerships with distributors, stone factories, and engineering contractors all over the world. Instead of sales that happen only once, the company is focusing on long-term relationships and to that end, it provides:

This cooperation model is very much appreciated by European and American buyers who put reliability and continuity on the top of their priority list.

Definitely! JingYang machines are of an industrial-grade standard and are built to be durable and sturdy thus they can do long hours of work at a stable level of performance.

The current CNC systems are easily operated by the users. JingYang also equips the users with training and operating manuals that are easy to understand in order to make the learning process short.

Generally, the machine will need regular lubrication, blade inspection and software updates. A well-maintained machine will have a long service life.

Sure! Depending on the dimensions of slabs, thickness of the cuts, automation level, and production capacity, JingYang will tailor the machine accordingly

Yes. JingYang provides international customers with technology support, documentation and spare parts supply, all remotely.

If a company is dealing with granite on a regular basis then a granite cutting machine is a good investment for them as long as they get such equipment from a reliable and experienced manufacturer. A granite cutting machine of superior quality will be an effective means of raising a company’s efficiency, cutting loses, widening service capabilities, and consolidating the competitiveness in the tough markets.

Thanks to decades of experience, solid records of certification, tried and tested technology, and the world-wide service capability, JingYang stands as a dependable partner for those enterprises who are after long-term value rather than short-term savings.

If you want to be sure of continuous quality, stable production, and sustainable growth then it is not just worth purchasing the correct granite cutting machine—it is necessary.