Selecting the appropriate stone cutting machine is a challenging task for the stone fabricator, contractor, and producer in Europe and North America. If you cut granite, marble, quartz, or engineered stone, the quality of your cutting tools has a direct bearing on productivity, accuracy, safety, and long-term operating expenses.

With so many models, technologies, and providers to choose from, buyers frequently feel confused.

The stone cutting machine is more than just equipment — it is the backbone of your production line.

A wrong decision can bring:

Uneven cutting accuracy of the blade

High material waste during processing

Frequent downtime and maintenance

Safety risks for operators and dust emissions

Poor long-term ROI

Conversely, the right machine increases cutting accuracy, reduces processing time, lowers labor dependence, and supports business growth.

Different stones require different cutting capabilities.

Granite requires higher power and rigidity, while marble needs smooth, vibration-free cutting.

A professional stone cutting machine should be capable of processing multiple stone types without sacrificing accuracy.

Modern buyers increasingly prefer stone CNC cutting machines with:

Automatic positioning

Digital control systems

Programmable cutting paths

These features ensure high repeatability and reduced operator error.

Small workshops prioritize flexibility

Large factories focus on capacity, stability, and continuous operation

It is crucial to match machine size and performance to actual production needs.

Even the best machine requires maintenance.

A reliable manufacturer with global service support is just as important as the machine itself.

JingYang (stonemachinerypro) is a professional stone machinery manufacturer with over 35 years of industry experience. The company has built an integrated system covering R&D, manufacturing, quality control, and global service.

👉 Company introduction:

https://www.stonemachinerypro.com/about-us

JingYang operates a customized production base exceeding 50,000 m², supported by hundreds of skilled engineers and technicians.

This scale enables stable quality, customized solutions, and cutting-edge innovation in stone cutting machinery.

What sets JingYang apart is its strict manufacturing discipline and quality management system:

ISO 9001 Quality Management System

ISO 14001 Environmental Management System

CE Certification for the European market

24-hour machine testing before shipment

These measures ensure that every stone cutting machine performs reliably in real working conditions, fully meeting European and North American safety and compliance standards.

JingYang holds dozens of valid patents in:

Structural design

Control systems

Stone processing technology

Through cooperation with universities and research institutions, JingYang continues advancing:

CNC control systems

Multi-axis cutting technology

Intelligent automation solutions

This strong R&D capability allows JingYang to offer:

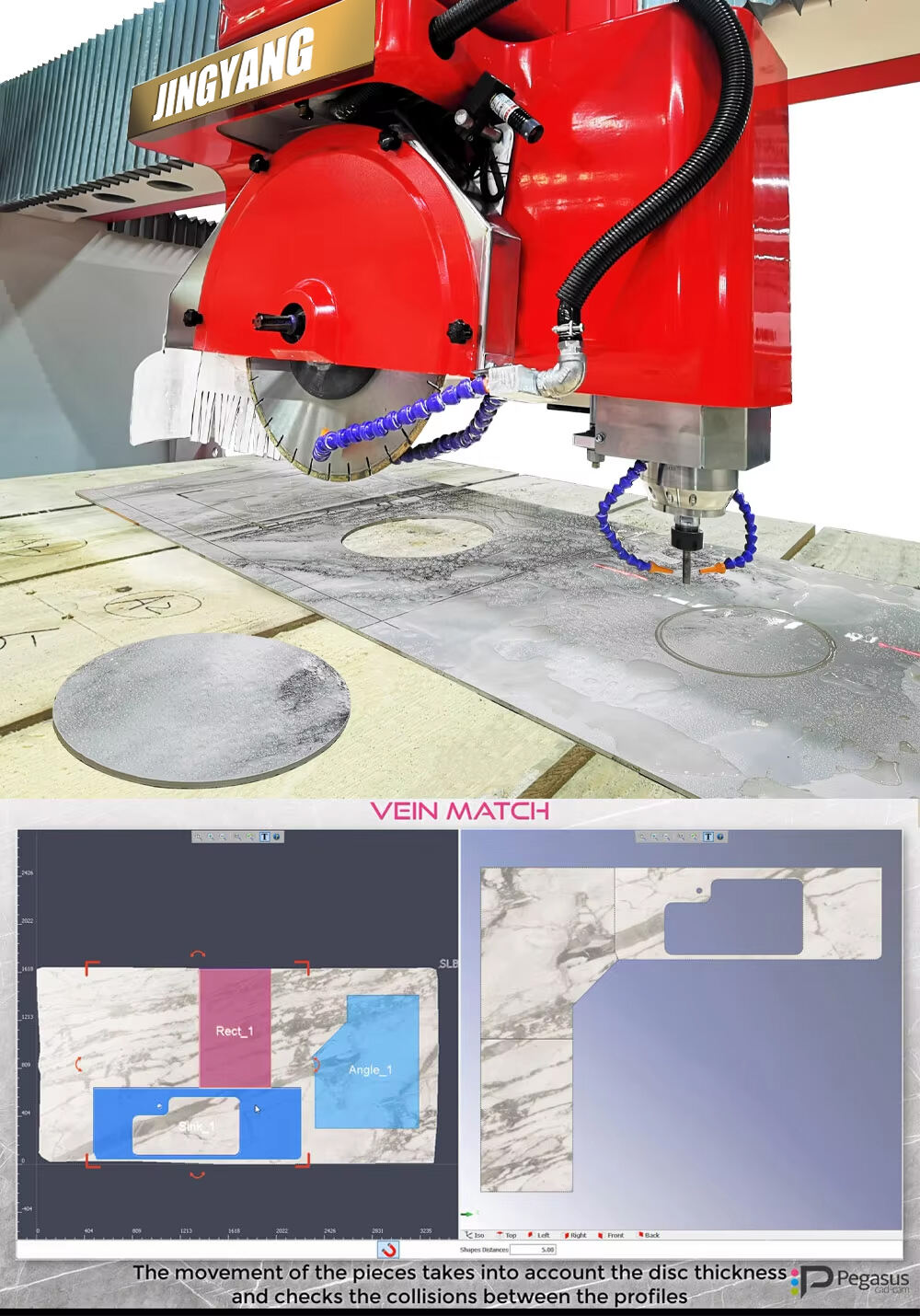

CNC bridge saws

Two-axis and multi-axis stone cutting machines

High-precision waterjet cutting systems

Customized solutions for complex projects

Innovation ensures long-term competitiveness in accuracy, speed, and energy efficiency.

A high-quality stone cutting machine is widely used in:

Precise cutting of granite, marble, and quartz slabs for countertops, sinks, and islands.

Production of facade panels, staircases, columns, and decorative stone elements.

High-precision carving and shaping of gravestones and memorial stones.

Customized stone flooring, wall cladding, and artistic stone designs.

JingYang machines deliver stable performance and flexible configurations to meet all these needs.

Here are authentic reviews from JingYang users worldwide:

“The cutting performance is very stable, even after long continuous operation. It saved us a lot of material and labor.”

— Stone Fabricator, Italy

“Installation and training went smoothly. The CNC system makes operation easier and faster, even for new operators.”

— Manufacturing Manager, Germany

“Maintenance costs dropped significantly, while runtime increased compared to our old machine.”

— Workshop Owner, USA

These testimonials highlight reliability, ease of use, and long-term value.

JingYang exports equipment to over 100 countries and regions, including Europe, North America, the Middle East, and Asia.

The company provides:

Pre-sales technical consultation

Customized machine configurations

Installation and commissioning support

Operator training

Long-term spare parts and maintenance service

This partnership-oriented approach gives customers confidence to scale operations sustainably.

Q1: Is the stone cutting machine CE certified?

Yes. All JingYang machines are CE certified and comply with European safety standards.

Q2: Can the machine cut granite and quartz effectively?

Absolutely. High-power spindles and rigid structures ensure efficient cutting of hard stone materials.

Q3: What is the delivery and installation time?

Delivery depends on configuration, but clear schedules and professional installation guidance are provided.

Q4: Do you provide operator training?

Yes. Training ensures safe, efficient, and correct operation.

Q5: How is after-sales service handled in Europe and the US?

JingYang offers remote technical support, documentation, and spare parts supply to minimize downtime.

Today’s buyers expect:

Proven manufacturing experience

Transparent production processes

Reliable certifications

Strong customer support

Long-term cooperation

JingYang meets all these expectations through experience, innovation, and customer-focused service.

So, how do you choose the right stone cutting machine?

The key is to focus on performance, reliability, service support, and long-term value — not just initial price.

By partnering with an experienced manufacturer like JingYang, buyers gain access to proven technology, global service capability, and machines designed for real production needs.

Whether upgrading equipment or building a new production line, the right stone cutting machine can dramatically improve efficiency, quality, and profitability.