Block cutters are undoubtedly the most common and the most important tools when it comes to the shaping of the raw materials necessary for construction, masonry, and stone-processing industries. Basically, these types of machines are used for cutting stones, bricks, concrete, or any other hard material to the size that is required for building projects. But, the main question here is how does a block cutter machine function? Knowing the unit operating mechanisms can help engineers to effectively use the machine, increase the output, and get better cutting results.

We will be discussing the bock cutter machine body, the work process, and the technologies that let reliable and accurate cutting in this paper.

1. A Block Cutter Machine Glimpse

A block cutter machine is a mechanical entity or instrument that cuts big blocks of stones or concrete into small pieces that are of the same size. The device changes various aspects depending on the type of material and the results one wants to get.

Old block-cutters depend on human labor, whereas recent models have features like automation, hydraulic power, and sophisticated control systems, which can improve the speed as well as the accuracy of the work performed.

Block cutter machines are the major sources of the next supply chain that is quarries, Construction sites, tile factories, and stone-processing plants. No matter it is granite slabs, marble blocks, concrete bricks, or sandstone that you want to get cut, the machine will be of high efficiency and the results will be consistence.

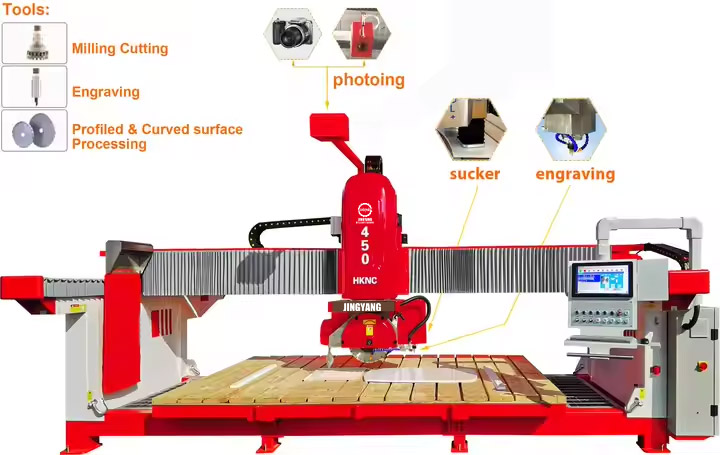

2. Core Parts of a Block Cutter Machine

Knowing the machine working can be better by first understanding the main parts of the machine:

a. Cutting Blade or Saw

The majority of block cutters utilize diamond-tipped circular saw blades or multi-blade systems. Diamond is the standard in the industry due to its ultimate hardness and wear resistance, which are the main attributes when cutting hard materials as granite.

b. Motor or Power System

The device can be electrically or hydraulically powered. A high-capacity motor (industrial models are frequently between 15 kW and over 75 kW) is a tool that needs to be run at high speed to bring about the cutting of the-edge blades.

c. Cutting Table or Platform

The workpieces are set on this platform. The table can be either immovable or it can be moved by means of the rails softly from one end to another to help the material feed into the blades.

d. Guide Rails and Frame

The blade head is fixed with long metallic strips that also guide it while moving up and down, thus helping the blade achieve not only a more precise depth of the cut but also giving it a stable movement.

e. Water Cooling System

A water jet is the only way to cool a blade, to dust off the cutting place as well as to make the cutting portion more accurate. What helps in the cooling of metal is continuous water flow which prevents overheating resulting in the metal getting dull.

f. Control Panel

The controls are digital or touchscreen in modern machines. Here by operators one can change the operation, i.e., cutting depth, blade speed, the number of passes made, as well as the cutting patterns.

3. The Working Principle of a Block Cutter Machine

The basic working principle is more or less the same for different models. Let's have a look at the step-by-step operation of a block cutting machine:

Step 1: Material Placement

A block of stone or concrete is securely placed on the cutting table. In case of huge industrial units cranes or forklifts may be used for loading heavy stone blocks.

Block alignment for the operator is the most important thing to get accurate cuts.

Step 2: Setting Cutting Parameters

Here is what an operator sets based on the material types and thickness:

- Blade height

- Cutting depth

- Cutting speed

- Passes number

- Blade rotation speed

- Water flow rate

It is possible for very advanced cutting machines to have stone type presets like granite, marble, or limestone.

Step 3: Blade Activation and Water Flow

Once the machine is running the motor accelerates the blade rotation to the higher speeds.

Water is also brought to the cutting area at the same time for the purpose of cooling and lubricating the blade.

Non-stop water:

- reduces friction

- prevents overheating

- removes the debris

- helps blade life be longer

Step 4: Cutting the Block

It is either the blade head that moves downwards into the block or the table that moves the block to the blade depending on the design of the machine.

There are mainly two cutting movements:

Vertical Motion

Blade is lowered gradually into the material until the desired depth is reached.

Horizontal Motion

The table or the cutting head moves to the end of the cut along a straight line.

The process can be repeated as many times as needed for deep blocks whereby, instead of a single heavy cut, multiple passes are used.

Step 5: Multi-Blade Cutting (if applicable)

Some block cutters have been fitted with multiple blades. Such machines can cut multiple slabs at the same time, thus the productivity is increased rapidly and the uniformity is maintained.

The multi-blade block cutters are heavily used in stone factories that are involved in the mass production of tiles and slabs.

Step 6: Finishing and Unloading

At the end of the job, the machine moves back to its initial position automatically. The operator then takes out the finished slabs or blocks.

Depend on the design of the machine, the transition from one step to the next could be done by manual handling, conveyor belts, or hydraulic lifters.

4. Different Types of a Block Cutter Machine

Manual Block Cutters

They are mainly tools for cutting bricks, paving stones, and small concrete blocks. The work is done by hand and the lever principle is used.

Electric / Hydraulic Block Cutters

Have been made for medium to large-sized materials and have more power, precision, and easy operation facilities.

Automatic and CNC Block Cutters

They use sensors and computers to achieve zero-error cutting patterns. They are most suitable for heavy industrial stone-processing plants.

5. Safety Features and Good Practices

Block cutter machines are very powerful and thus require safety measures to be taken seriously.

Some of the safety measures that are commonly found in such machines are:

- Emergency stop buttons

- Blade guards

- Anti-slip working platforms

- Automatic water flow sensors

- Overload protection

Good operating practices are:

- Using protective gear

- Making sure the water-cooling is done properly

- Not wearing loose clothes

- Regular blade maintenance

- Keeping the work area clean

6. The Reason Why Block Cutter Machines Are Invaluable

First of all, block cutter machines have the following advantages:

- High precision and consistency

- Much faster processing as compared to manual cutting

- The capability of cutting extremely hard materials

- Enhanced safety and cleanliness

- Labor cost reduction

- Increased efficiency for industrial production

By using these machines on the different stages such as quarry operations and construction projects, you make sure that the blocks are being cut in a very precise and less time-consuming manner and hence are ready to be used for flooring, walls, countertops, and architectural elements.

Conclusion

A block cutter machine is the most powerful and a pretty indispensable tool when it comes to cutting stone and concrete into required shapes and sizes. The machine brings precision, efficiency, and constant performance together by pairing the hefty diamond blades, the powerful motors, water for cooling, and automated controls. No matter if it is done for granite slabs, concrete bricks, or marble tiles, block cutters are a means of simplifying the whole production process and increasing the overall output.

Understanding a block cutter machine working, knowing its parts, working principles, and safety measures will definitely help in the giving of effective as well as safe operations if ever such a machine is your need.