- Overview

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

High volume fabrication is usually faced with the actual critical profitability issues, the inconsistent hardness of the slabs, slow throughput of material flow, and high labour costs for rework. Our engineered response is our HLMJX-20C. With 20 independent grinding heads and 311 kW gross power, this system provides a mirror-like, industrial-grade, consistent finish. The machine itself is controlled by an intelligent PLC electrical system and LCD screen menu, so that the operator has the ability to accurately control the whole finishing process with unparalleled ease and definition.

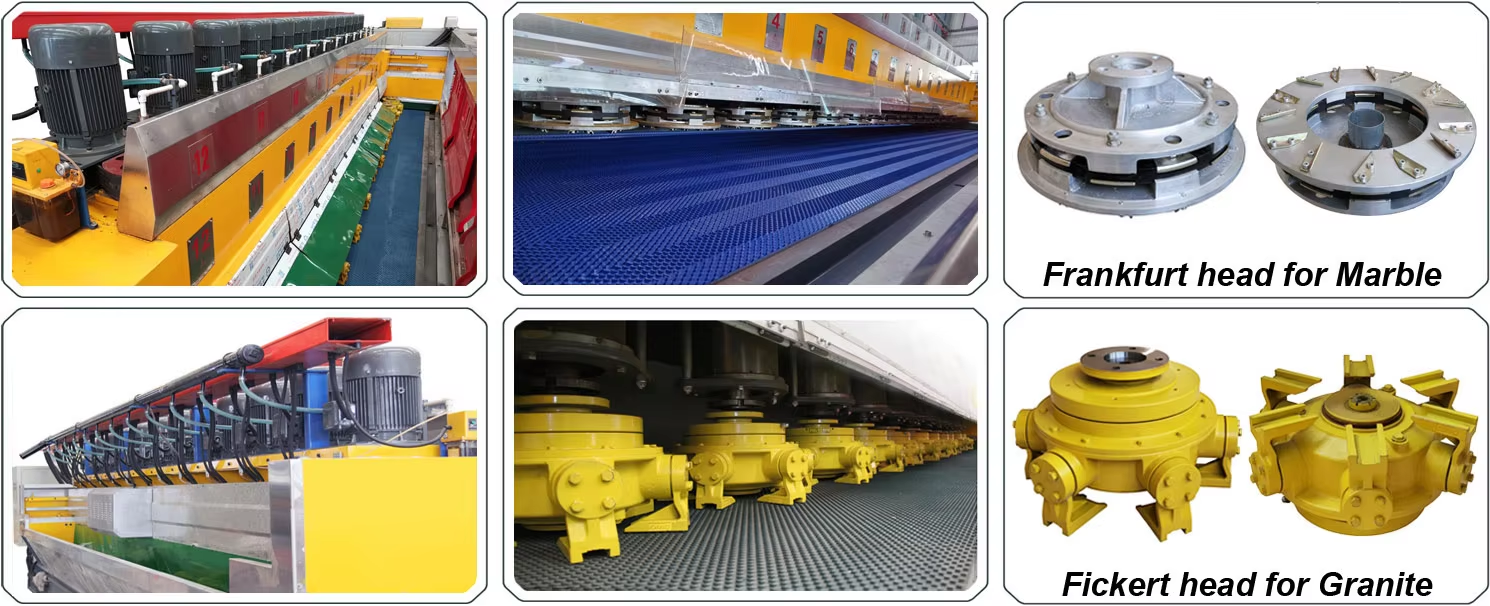

This smart control is crucial for solving material variation: the working pressure and processing width of the P-grinding heads can be freely adjusted, ensuring that softer marble is not damaged while harder granite receives the exact necessary force. This continuous flow machine is designed to deliver a minimum throughput of 250m²-300m² per hour.

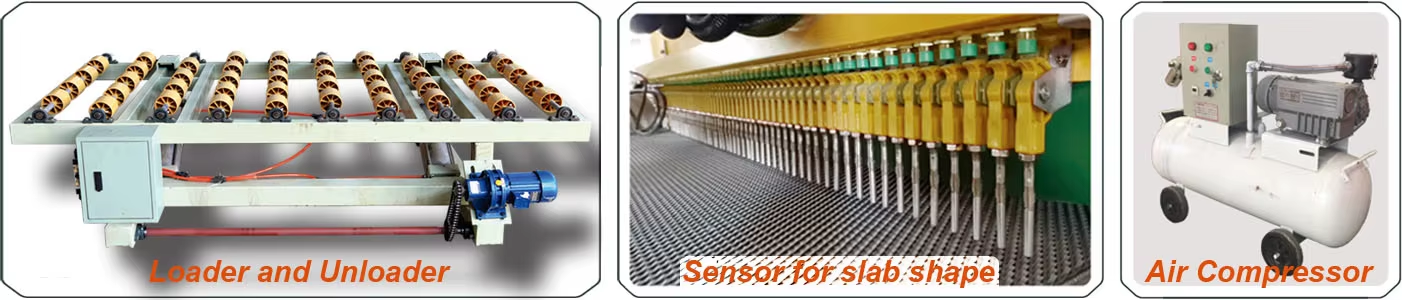

Accuracy contour scanning addresses the greatest challenge in precision scanning, namely, edge integrity. As the slab enters, a series of sensors scan the shape of the slab in order and transmit data to the control unit, which guides the work. By using the full 2100 mm working width, the process is banked to perfect edges and eliminates the potential for edge rounding and over-polishing the waste material.

Each of the 20 heads is driven by a 15kW spindle motor that provides constant torque over the 2100mm working width. The machine has a gross power of 311kW, which remains constant even when running at the maximum belt speed of 3500mm/min.

|

TECHNICAL DATA |

|||

|

Model No. |

HLMJX-12C |

HLMJX-20C |

|

|

Number of grinding head |

pc |

12 |

20 |

|

Power of spindle motor |

kw |

15 |

15 |

|

Gross power |

kw |

201 |

311 |

|

Useful working width |

mm |

400-1300 |

300-2100 |

|

Useful working thickness |

mm |

10-80 |

10-50 |

|

Speed of belt advance |

mm/min |

0-3800 |

0-3500 |

|

Water consumption |

m3/min |

20 |

30 |

|

Gross weight |

kg |

21000 |

32000 |

|

Demension (L x W x H) |

cm |

9700*2200*2650 |

1400x309x235 |

Marble Slab Polishing: Achieve high‑gloss finishes and even surfaces for countertops and decorative wall panels.

Quartz and granite finishing creates a consistent sheen on the big slabs utilized in bathrooms, kitchens, and business floors.

Engineered Stone Processing: Polish sintered and composite slabs under controlled pressure to reveal consistent patterns.

Mass production is ideally suited for batch runs in fabrication plants that require constant throughput and low handling.

Profile Honing: Polish and finish the cut edges to create custom profiles, bullnose, ogee, and bevel finishes.

Pre-installation preparation entails the final surface preparation of cladding panels, stair treads, and niche surrounds.

Automatic lubrication: A central lubrication system automatically lubricates all the moving parts and bearings, causing them to live longer. Instead of predetermined time intervals, it monitors a cumulative number of operating hours, and it has been shown that components last 15% longer, greatly reducing expensive unscheduled downtime.

Effective debris management: Self-cleaningconveyor combined with chip removal system solves the problem of surface quality caused by slurry re-contamination. The result is a consistently clean abrasive-free work against during the final stages of polishing.

Labor and space savings: Consolidation of four to five polishing stations into one machine, the HLMJX-20C saves 30% on shop floor space needs and requires labor of approximately 1 full-time workers per shift.

Q:What is the MOQ?

A: 1 set.

Q: When will you ship my order?

A: Normally 25-35 days after deposit received, If urgent, it can be negotiated further.

Q: Are you trader or manufacture?

A: We are a leading manufacture in stone machinery for more than 30 years.

Q: What's the warrenty?

A: 1 year, but the technical support is lifetime.

Q: How can you guarantee the quality?

A: We have a professional quality control team, they will seriously inspect every manufacturing procedure during production. Also we will give every machine a overall check before delivery.

Q: Why should I buy your from you, not others?

A: We have professional R&D team in this industry over 30 years, experienced workers, responable QC team, good quality, competitive prices and excellent survice.