In 2025, the worldwide stone industry keeps moving forward at an unprecedented speed. The stone sector is not only about the traditional use in building and carving of monuments but also creative design of interiors as well as artistic stone crafts. With that, the need for more accuracy, timeliness, and personalization is constantly increasing. As a result, several potential buyers particularly in Europe and North America end up pondering a fundamental question: Is a stone engraving machine a good capital venture at all in 2025?

This piece will respond to that inquiry in simply a practical, people-oriented way, based on the actual requirements of the industry, the user feedback as well as revealed manufacturing expertise. Besides, we will also present JingYang, the professional stone machinery manufacturer and will indicate how their know-how and solutions enable businesses to win in an ever tougher market.

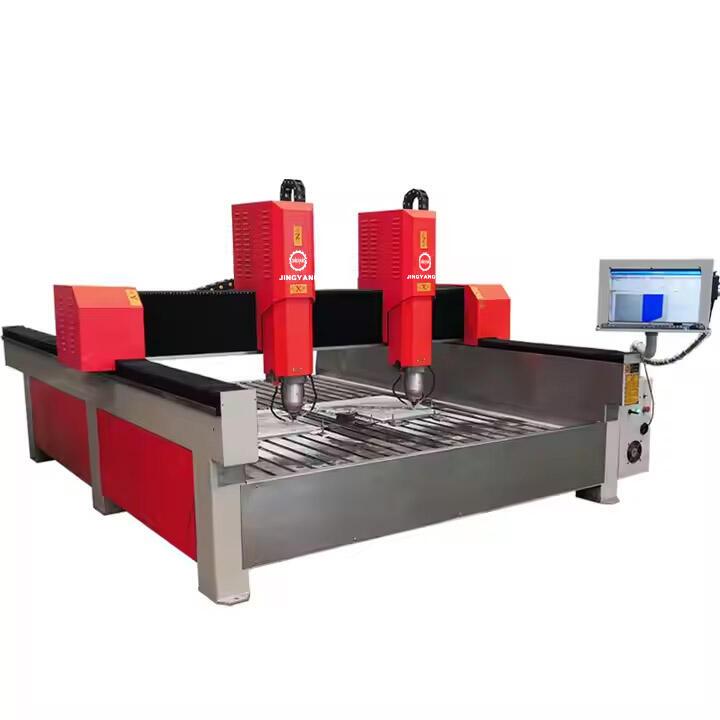

A stone engraving machine is a CNC-controlled equipment that works on carving or decorating stone surfaces by segments, words, paintings, 3D designs, etc. to name the most common raw materials are marble, granite, quartz, limestone, and artificial stone. The significant differences between hand engraving and a modern engraving machine are:

Today these machines are used for tombstone engraving, architectural panels, decorative stone walls, countertops, signage, and artistic stone products.

There are numerous worldwide trends in the industry, which globally increase demand:

The answer briefly: if you pick the proper equipment and a partner, then yes.

One cannot see a stone engraving machine just as a machine; rather, it is a work-enhancing tool that can be kept for a long period. Those firms which have been right in making an investment have reaped benefits such as:

Nevertheless, the factors that machine quality, technical support, and the manufacturer's familiarity with the field quite important play a role in determining success.

JingYang is a historically stable stone machinery manufacturing business that has more than 35 years of experience in the industry. According to the company´s official introduction (https://www.stonemachinerypro.com/about-us), JingYang combines research, manufacturing, sales, and service performing these activities sequentially in one system.

Primary capabilities include:

As a result, potential customers not only trust the product but also feel at ease with the provided long-term assistance and progress.

Stone engraving machines are used mostly for indexing, faces, logos, and religious ornaments, as well as the memorial pieces. The carved characters would be clear and long-lasting through the precise depth control mechanism.

Hotels, villas, museums, and offices are places bestowed with luxurious engraved-stone walls. The geometric and cultural patterns made in the same way can be repeated without deviation.

Stone CNC engraving plays a significant role in giving a luxurious touch to the stone interiors starting from countertop engravings to wall tiles decorated with patterns.

Engraving machines help the artists and cultural centers to perform reliefs, sculptures, and restoration at the ever-increasing level of accuracy.

Michael R., USA (Stone Workshop Owner)

“We could double our speed of production when we introduced the JingYang stone engraving machine to our factory. The machine is particularly good at the ability of very accurate artwork execution of the text.”

Thomas L., Germany (Architectural Supplier)

“We were in dire need of the consistent quality of our engravings in the preparation of the big projects. The machine works efficiently, and the technical team of JingYang is always willing to help.”

Emily S., Canada (Monument Business)

“Once the customization was a slow and costly procedure. Today, we have no problem with personalized productions though the delivery time is not extended.”

Usually, these check-ins revolve around common elements: efficiency, accuracy, and reliable support.

Stone engraving machines nowadays from the top of the line manufacturers like JingYang highlight:

The university collaboration of JingYang during a long period and also continuous R&D investment have made sure that depending on their machines, the ever-changing world standards can be met seamlessly.

JingYang collaborates with distributors, stone factories, and project contractors worldwide. Long-term cooperation is built on:

To a lot of overseas partners, JingYang is more than just a supplier—they consider it their strategic manufacturing partner.

Today’s machines have user-friendly CNC operating systems. JingYang offers training sessions and technical supports that help the operators to get familiar with the machines in a short time.

Marble, granite, quartz, limestone, artificial stone, and other materials of the same nature can be engraved.

If adequately taken care of, a proven stone engraving machine can remain in use for many years.

Definitely. Buyers from overseas ought to give priority to such manufacturers that not only have competent technical support but also spare parts readily be available which is an area where JingYang excels.

Sure. Depending on the client's workspace, spindle power, control systems, and application needs JingYang gives the option of customization.

In 2025, a stone engraving machine can be said as a necessity rather than a luxury. It is a strategic move of a business to stay competitive. If combined with a dependable manufacturer like JingYang, the advantages will not be limited to mere automation only: higher quality, shorter delivery time, wider range of services, and long-term growth.

If your business is all about precision, efficiency, and customization, then the answer for you is quite obvious: a stone engraving machine is really a great investment.