- Overview

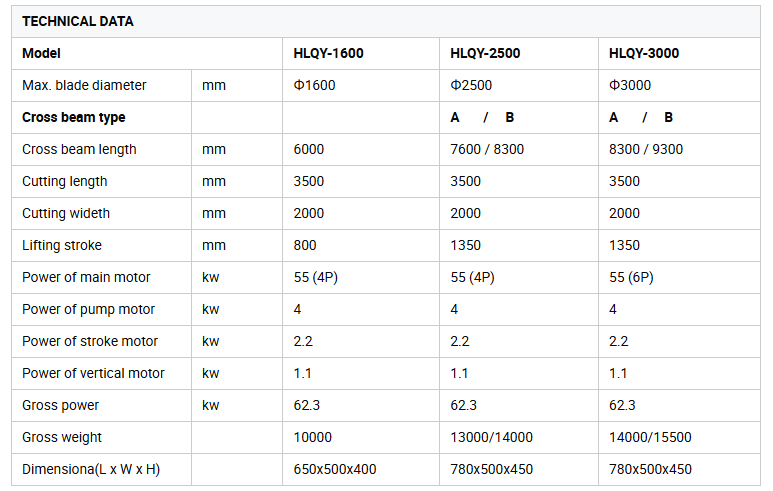

- Specifications

- Applications

- Advantage

- FAQ

- Recommended Products

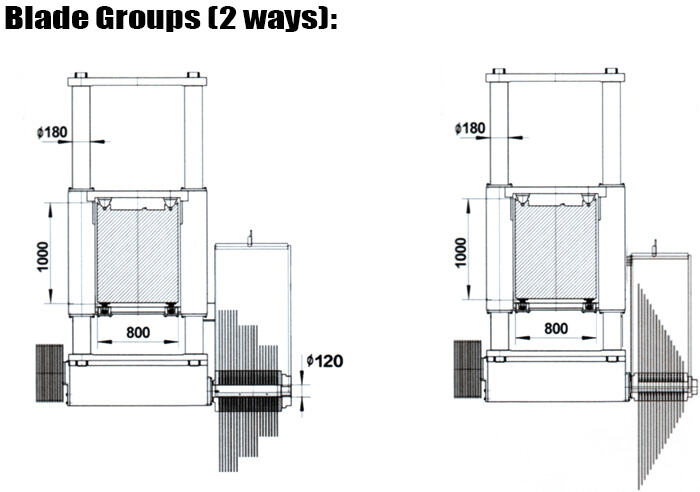

The HLQY-32-1700 Multi-blade Bridge Saw is created to convert large pieces of stone into thin or thick slabs - and to do it every time, with high accuracy, and in the shortest time possible. The HLQY-32-1700 is a combination of a Siemens PLC intelligent control, a high rigidity bridge beam, and Hiwin oil-immersive linear guides made in Taiwan, to give stable cuts in granite, marble, and sandstone. It has the potential to use up to 18 thin blades, so that it can optimize material yield and cutting throughput and significantly reduce machine deflection and component wear, thus becoming the reliable option for fabricators that require both precision and productivity.

Max. Processing Dimensions (LxWxH): 3200 x 2000 x 2000 mm

Spindle Power: 55 kW

Max. Number of Blades: 18 pcs (Ultra-thin)

Cutting Accuracy: ≤ ±0.05 mm

Slide Synchronization Accuracy: ≤ ±0.03 mm

Main Beam Structure: High-rigidity, large-section bridge type

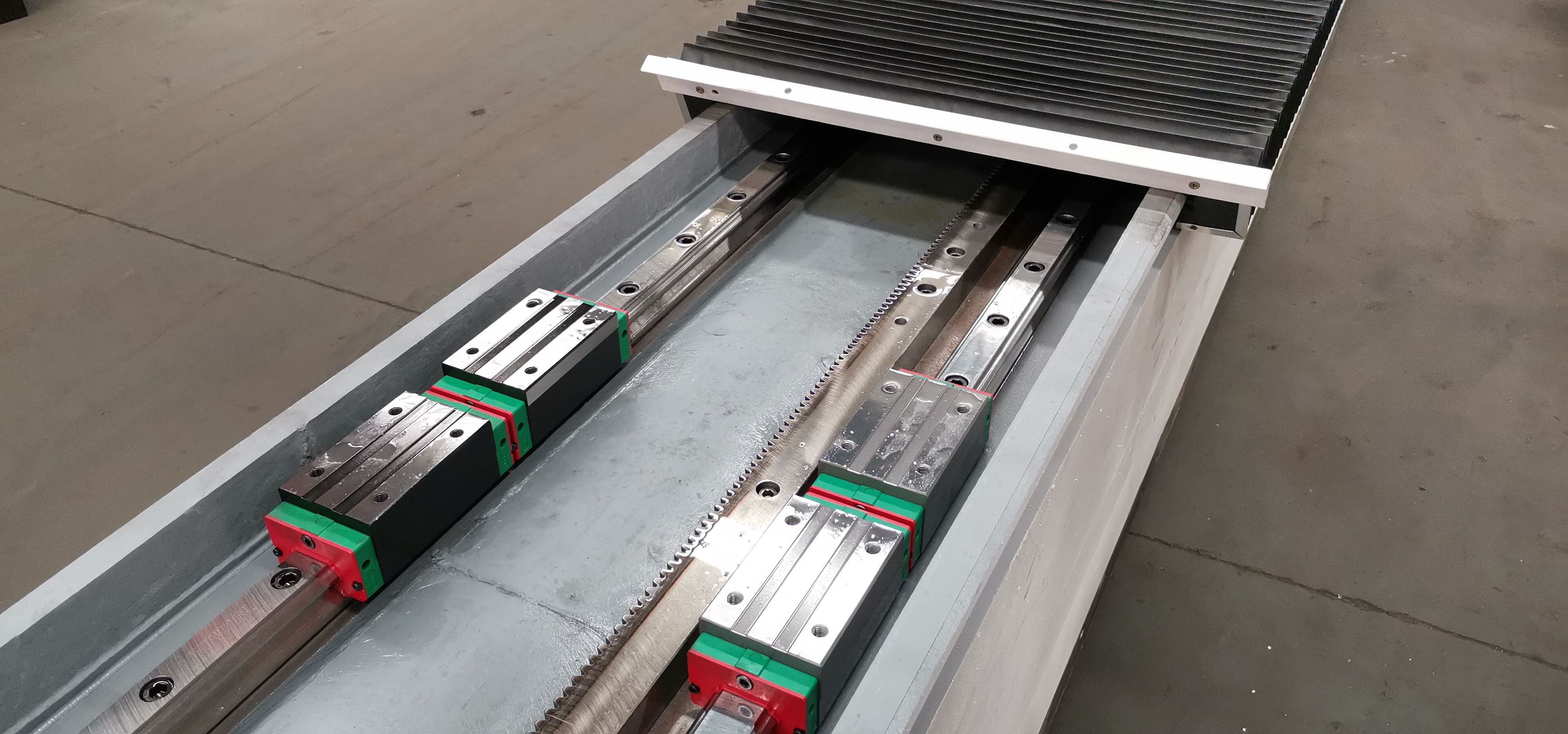

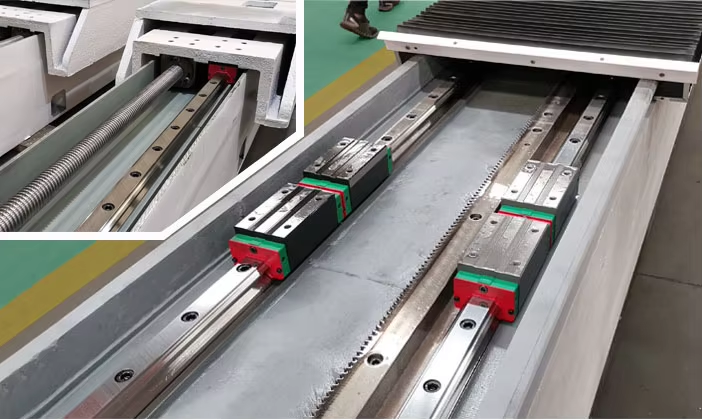

Guide System: Taiwan Hiwin Linear Guide with Oil Bath Lubrication

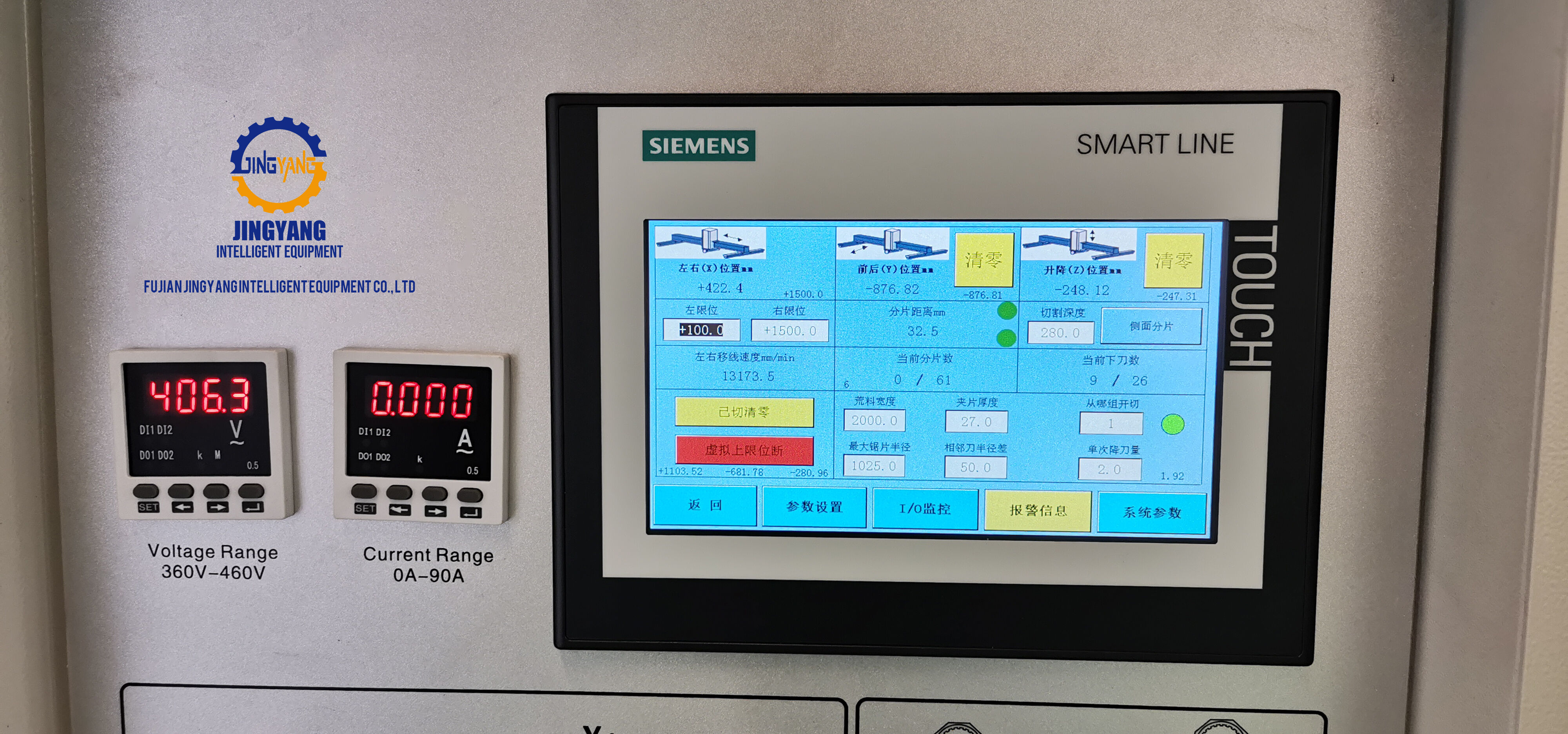

Control System: Siemens PLC with HMI Touchscreen

Drive System: X/Y-axis: Rack and Pinion; Slide: Mechanical Screw Synchronization

Warranty: 12 Months

HLQY-32-1700 is designed to machine slabs naturally with high efficiency. Its 55kW high-power spindle and variable blade arrangement (up to 18) give the required cutting force (Fc) and density to cut materials with different tensile resistance (Rm).

Main Materials: Granite, Marble, Sandstone, Limestone, and other composite stones.

Slab Thickness: The 10mm to 50mm thick slabs can be efficiently produced, and the range of 18mm to 30mm will be optimal in terms of production and surface quality.

Common Applications: High production output plants of slabs, stone Export processing bases, and processes requiring high output and uniform quality, from one block to finished slab.

1.Reliable Multi-Axis Coordination with PLC-Based Intelligent Sequencing

In complex stone cutting processes, manual or basic electronic controls often lead to errors, inconsistent responses, and downtime. The HLQY-32-1700 centers on a Siemens PLC as its core, combined with a user-friendly HMI. It integrates spindle control, sliding motion, feed sequencing, and safety logic into a unified system. Each critical activity operates based on stored process parameters; thus, operator skill level has minimal impact, ensuring consistency across shifts and batches. This translates to smoother production, easier training, and higher overall efficiency.

2. High-stiffness bridges minimize deviations caused by beam deflection

During large-scale or thick-plate cutting operations, beam deflection and structural vibration are the primary causes of thickness variation and cutting deviation. Essentially, beam deflection can be analyzed as follows:

δ = (F * L³) / (3EI),

where F is the cutting force, L is the span length, E is the material stiffness, and I is the sectional moment of inertia. Structurally, deflection increases rapidly with rising cutting force and span length, while decreasing with increased beam stiffness and sectional inertia. The HLQY-32-1700 employs a large-section box-type beam constructed from high-rigidity materials, enhancing bending resistance and suppressing source vibration. This ensures a more stable and linear cutting path, particularly advantageous for processing large-scale panel blanks, thereby reducing rework and material waste.

3. Oil bath protection for guideways reduces precision loss caused by abrasive dust.

Stone dust is particularly problematic because it is hard and abrasive. When it contacts the guideway surface, it accelerates wear and compromises accuracy.

The service life of rolling guides typically follows L₁₀ ∝ (C / P)³, where C represents the dynamic rated load and P denotes the actual load, including wear caused by contamination.

Oil bath lubrication offers an advantage by maintaining a constant oil volume, preventing direct contact between abrasive particles and the guide surface. Therefore, combining Chinese Taiwan Hiwin precision guides with oil bath lubrication is beneficial for ensuring the HLQY-32-1700 maintains accuracy throughout its service life while minimizing maintenance-related downtime.

4. Multi-blade configurations reduce kerf loss and increase output

In multi-blade sawing operations, material loss primarily results from the combined kerf formed by all blades. Material utilization efficiency can be determined using the following formula:

Utilization Rate = St / (St + Sk),

where t represents the slab thickness and Sk denotes the blade kerf width. The HLQY-32-1700 supports up to 18 blades and incorporates thin-core blades, enabling increased thickness production while minimizing kerf loss. Thin-slab and gemstone applications benefit most significantly, as waste costs directly translate into profit margins.

5. Mechanical Synchronization Dual Sliders Prevent Asynchrony

Additionally, when the saw vibrates or encounters unexpected loads, the electronic dual-drive system may experience synchronization issues. This occurs when minute variations in the slide translate into differences in slab thickness. In such cases, the HLQY-32-1700 employs “rigid mechanical synchronization” to address the requirement for synchronized sliders. This involves the simultaneous movement of sliders controlled by the same gearbox, ensuring their geometric positions remain in phase—i.e., ΔX_left = ΔX_right.

6. Reducing vibration and path errors lowers polishing requirements.

The primary factors affecting surface roughness in these systems are vibration and its effect on tracking the designed path.

This can be summarized as Ra ≈ C1·v + C2·e, where v represents vibration and e represents any trajectory error in the path.

The HLQY-32-1700 mitigates these issues through its rigid beam, stable path, and motion PLC control. All these factors reduce vibration and tracking errors, enabling smoother path completion with less polishing output.

Overall productivity can be viewed through the lens of stability, speed, and accuracy. Without stability, maintaining speed and accuracy becomes impossible. The HLQY-32-1700 delivers a first-class solution by integrating rigid construction, high-precision motion components, a PLC control system, coordinated mechanics, and a robust drive system. Even in heavy-duty production, the combined effect of these measures creates stability, laying the foundation for sustainable profitability.

Q: Is JINGYANG a trading company or a manufacturer?

A: JINGYANG has its own stone machinery factory with independent research & development and production. The HLQY-32-1700 is produced in-house and supports OEM/customization, factory inspection, and video demonstration.

Q: How long does it take for the HLQY-32-1700 to be shipped?

A: After confirmation of deposit and locking down the technical options, the usual lead time for production would be approximately 3 to 5 weeks (about a month). In the case of special customization requests, high volume orders, or peak periods, the delivery schedule would be mutually agreed upon in the contract.

Q: What is the warranty period and after-sales service for the HLQY-32-1700?

A: We provide a 12-month warranty service.

Q: Which international certifications and safety standards does this machine include? Do all the website machines meet?

A: The stone machine including The HLQY-32-1700 have passed the European CE certification and fully meet international safety standards.

Q: Can I request OEM customization?

A: Yes. We support OEM customization for each customer's requirements. Factory inspection or video acceptance is welcome.

Q: How to get the most competitive quotation?

A: Hello, accurate quotation needs to be based on your specific needs assessment. Welcome to contact our sales team to provide you with a detailed plan.